The Alessandro 1895 Shoe

The shoes

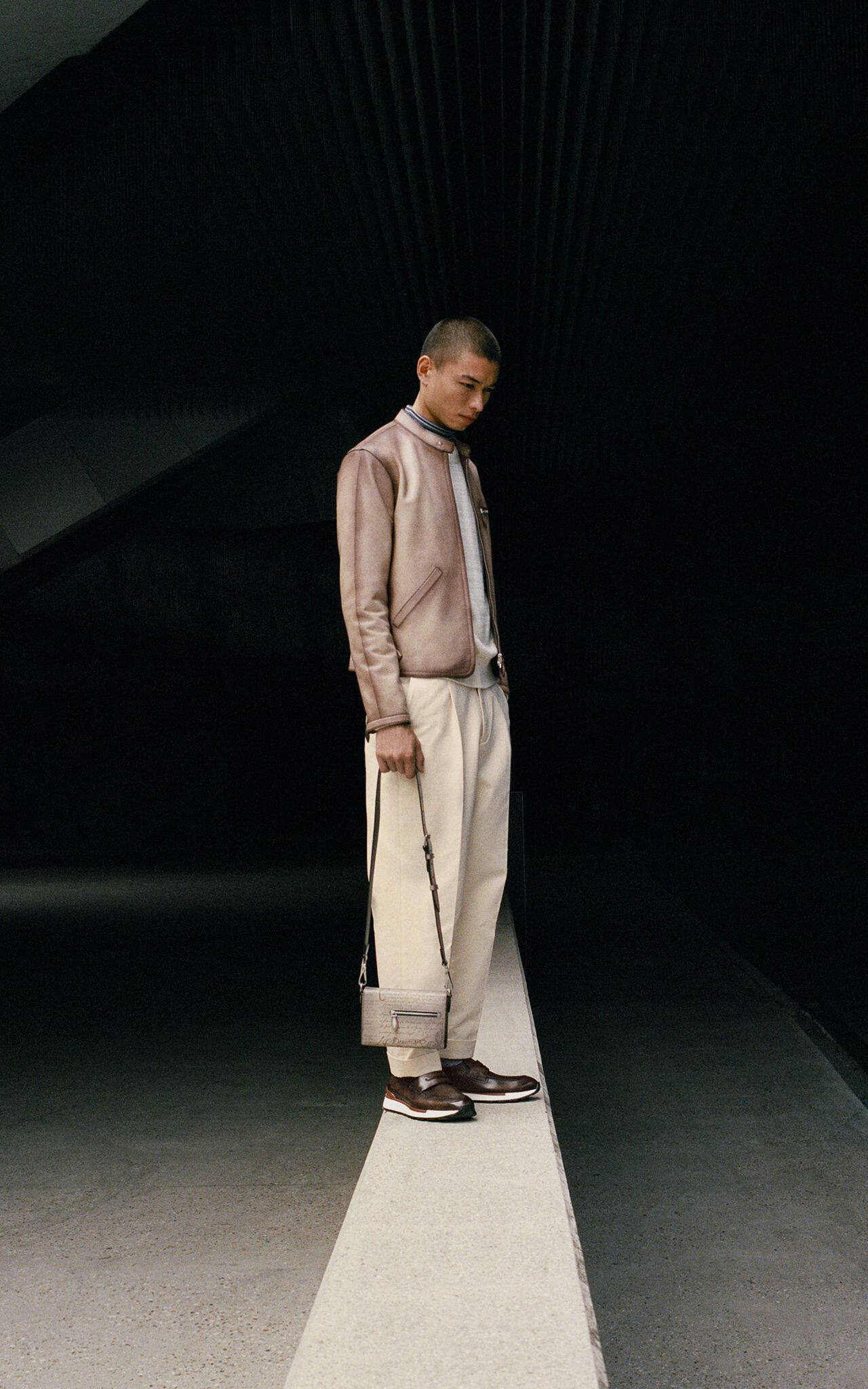

The Ready-to-wear

The Bags

The Aquarelle Jacket

The Un Jour De Poche Messengers

A selection of Berluti’s finest pieces, exclusively tailored for your wardrobe.

The Maison unveils its New Campaign

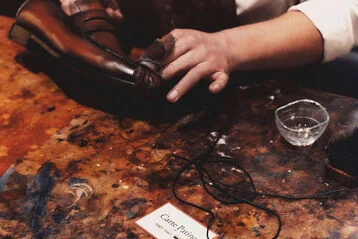

The Forestière, Precision in every Gesture

Berluti at your Service

Choose Your Country/Region

Please select your location to shop online.

Can't find your country?

Discover our International website.

Welcome to Berluti

We noticed that you are accessing the United-States of America Berluti website.

Please select your location to shop online or to explore berluti.com

Page does not contain any content.

Welcome to Berluti

Let’s keep in touch. Be the first to discover Berluti’s exclusive collections, our new products and hear about our private events.

By subscribing, you agree to our privacy policy