CREATIVE CIRCULARITY

SUSTAINABILITY IN ACTION

Creating while respecting nature

Because they are timeless, Berluti products are intended to be sustainable. Respect for the environment and the preservation of natural resources are the Maison's priorities at every stage of their life cycle. Their design requires materials selected according to the most demanding criteria, crafted in such a way as to reduce the volume of material used, while limiting waste.

Scrap leather, metal, fabric and wood are recycled or redistributed for other purposes. In stores, plastic has completely disappeared from customers' packaging, which now favors paper and cardboard from eco-managed forests as well as recycled materials.

Optimizing packaging

In stores, the customer packaging is simple, elegant and respectful of the environment. Plastic has been completely abolished. The cardboard is derived from sustainably managed forests. The felt and cord are made of cotton. In order to preserve natural resources, the proportion of recycled materials (post-consumer waste) used in customers' packaging is increasing; it reached 68% in 2023.

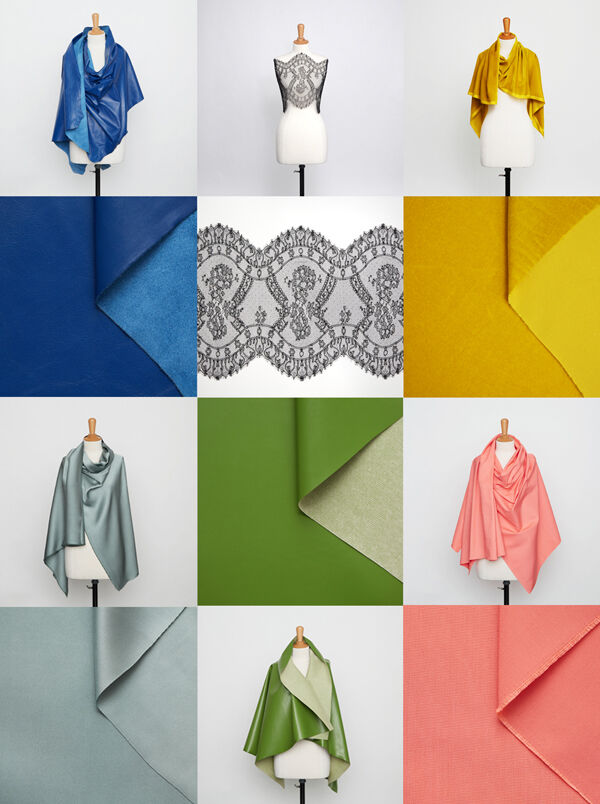

Pulling the thread of the circular economy

Created in 2021 by the LVMH group to promote the circular economy, Nona Source is the first online platform offering the resale of exceptional materials from its various Houses. It makes high-end fabrics and leathers from unused inventory available to young designers and brands in Europe. Berluti sells almost 30% of its leftover materials through the platform*. The remaining 70% is collected by a partner who sorts the scraps by type. According to their nature, they are processed to make fertilizer, foam insulation, or filling for the automobile industry. These creative, circular solutions aim to make the future of fashion ever more virtuous.

*Data as of September 2023

Imagining eternal products

It takes several days to craft a pair of shoes, months when they are custom-made. But they are intended to last a lifetime. They are protected by the exclusive tanning of our leathers and the meticulous care given to their patina. Regularly maintained, polished with wax and nourished by their owner or in one of the Maison's stores, the shoes stand the test of time, maturing like fine wine. At the slightest snag, at the appearance of traces of wear on the sole, the craftsmen in the workshops are able to restore the damaged part, giving the shoe the eternal character of a precious jewel.

Invitation to care

Quality is the outcome of absolute care. The choice of the most noble materials, the 250 operations necessary to make a pair of custom-made shoes, the attention paid to each step by the Master Bootmaker mean that they are durable objects by essence. However, regular maintenance remains the key to giving them a long life. Taking care of them yourself, following this online tutorial, is a delight for the senses. Berluti also recommends that its customers visit the store at least once a year to have their shoes restored and keep them looking their best.

Fighting obsolescence

Custom-made shoes are not the only items that can be refurbished. Whether leather goods or ready-to-wear, Berluti's goal is to make every item repairable. Even some sneakers can now be resoled. The process of using components from unsold products in after-sales service is underway.

79% of the shoes and leather goods available in the 2023 Berluti catalog are already repairable. By 2030, this proportion will increase to 85%.

To ensure that our leather products remain elegant for as long as possible, each client receives a complimentary "first patina." This beauty ritual extends the length of the product's lifespan. Through the care and repair services that Berluti offers customers, the Maison clearly shows its commitment to the durability and repairability of its products.

A second life for a second chance

Since January 1, 2022, the French law known as AGEC (against waste and for the circular economy) prohibits the destruction of unsold non-food items. Through a partnership with a sheltered workshop (ESAT) where disabled workers remove the labels, Maison Berluti offers these items a second life by donating them to selected charities, recycling them or upcycling them, i.e. transforming them into new items. The impact is both ecological and social, because the associations concerned help the people they employ reintegrate the world of work. The Maison intends to take advantage of the experience it has accumulated in France to share it in the other countries where it operates by 2030.

Donations to help people return to work

La Cravate Solidaire's mission is to strive for equal opportunities. This French network of associations fights against discrimination in recruitment. It restores confidence to those who need it by helping them to fit in with the culture of the company. Meanwhile, Agence du Don en Nature helps the most disadvantaged people in France by distributing new non-food items. These are the two organizations to which Berluti has chosen to entrust a portion of its unsold items. Eventually, after they have been anonymized, more than half of them will be redistributed and other initiatives will be carried out internationally.

Promoting integration through upcycling

Tissons la Solidarité brings together 70 French professional integration organisations. Their main occupation involves collecting, sorting, transforming and selling textiles. Nearly 1,900 employees, 83% of whom are women, receive guidance towards finding employment. Berluti has chosen this network to recycle some of its unsold goods. After a successful initial test in 2021, the proportion of unsold goods and used sales personnel uniforms that are upcycled or recycled will increase, and is set to reach 50% by 2026.

Recycle rather than throw away

During the various manufacturing processes, it is not always possible to use all the raw material. Some unused components may become obsolete. Berluti is committed to recycling almost all of them by 2030. Currently, 75% of its leather offcuts are already transformed into fertilizer. In late 2022, the Italy-based Manifattura Berluti established separate, ongoing collaborations to recycle rubber sole scraps and metal parts. One partner uses 100% of the rubber sole scraps to surface running tracks. Another partner melts down 100% of the metal parts to be cast as new pieces. Other components could soon also enter into a system that offers them a second life.

.jpg)